With new materials available, manufacturers are exploring 3D printing to create functional prototypes and parts that were previously only possible with CNC milling and turning.

Which technology is right for your application?

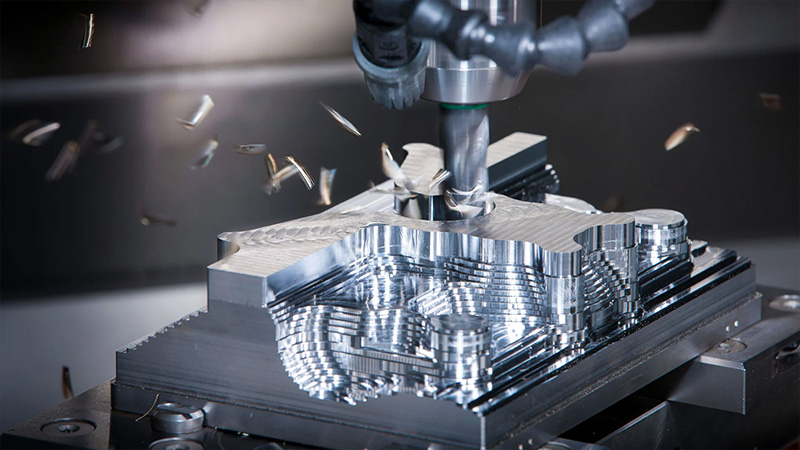

CNC Machining

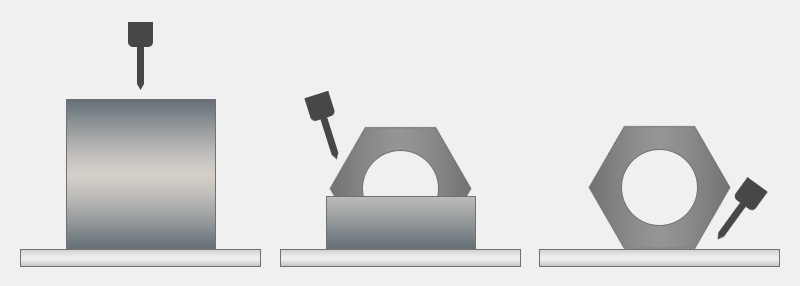

CNC machining is a subtractive manufacturing process that removes material from a solid block of material (called a blank) with tools or cutters to achieve the final shape. CNC machining achieves high accuracy, repeatability, and a wide range of materials and surface finishes.

Advantages

- Precision and repeatability

- Medium-high quantities of identical parts

- Can create larger parts

Some geometries are impossible to CNC machine, even with 5-axis systems, as tooling cannot access all of the surfaces. While CNC can create complex parts, increased complexity often means increased cost.

CNC machining process

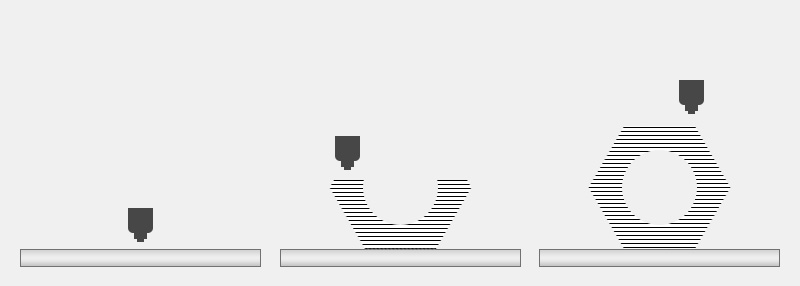

3D Printing

3D printing or additive manufacturing builds parts by adding layers of material until the object is created. M3DP (Metal 3D Printing) is an emerging technology with its own specific advantages and drawbacks. M3DP offers reduced material waste, efficiency, and greater design freedom.

Advantages

- Very low up-front costs

- Small runs (10 or less) of identical parts

- Materials that can’t easily be machined

3D printing is generally better for low quantities, one-off prototypes, and complex geometries. 3D printing may also be a more viable option if using exotic materials.

3D printing process

Selecting the Right Process

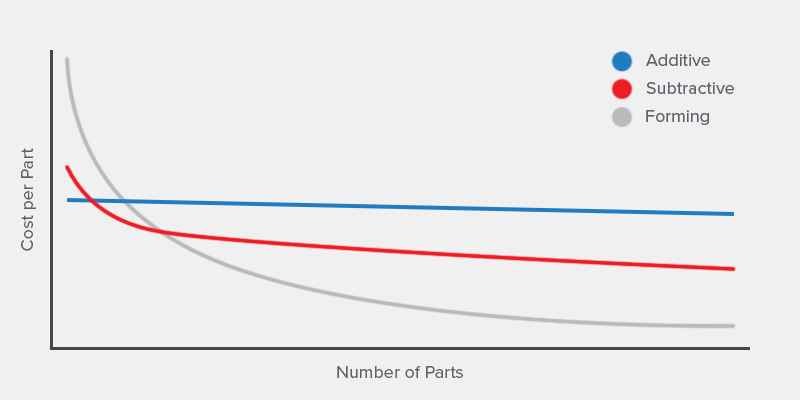

CNC machining and 3D printing technologies compliment each other, and can even be combined. It’s not a matter of “which is best,” rather “which is better for my application?” Due to economies of scale, other forming options are also viable for larger quantities of parts:

Injection molding, stamping, and casting have high start-up costs because new tooling and molds need to be created. However, as the number of parts created increases, those forming options become more and more economical.

Key considerations

- Complexity

- Precision requirements

- Number of parts

There is no one-size-fits-all solution. The most appropriate one for your application will depend on the material, geometric complexity, manufacturing volume, and budget. 3D printing technology is still developing, and although advancements are being made, it is still limited in the materials and benefits it offers.

CNC is often a more accurate and higher quality method for manufacturing prototypes and parts, especially metal. FabMetals offers a variety of CNC machining services – request a quote for your project today.